Don't miss our holiday offer - 30% OFF!

How Does A Crushing Screen Improve Material Processing?

Material processing efficiency is crucial for industries relying on heavy industrial equipment like crushers and mills. Among the many components contributing to this efficiency, crushing screens play a pivotal role. Understanding their function and benefits is essential for optimizing material processing operations.

Introduction: Understanding Material Processing Efficiency

Material processing efficiency refers to the ability to handle raw materials effectively, minimizing waste and maximizing output. In industries like mining, construction, and recycling, where large volumes of materials are processed daily, efficiency is paramount. It encompasses various factors, including equipment performance, energy consumption, and throughput rates. Achieving high efficiency not only improves productivity but also reduces operational costs and environmental impact.

The Role of Crushing Screens in Material Processing

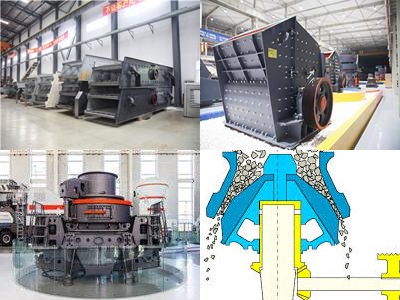

Crushing screens are integral components in material processing systems, facilitating the separation of materials based on size and ensuring uniformity in the final product. These screens, often vibrating or rotating, sift through crushed material, separating finer particles from larger ones. By controlling the size distribution of output materials, crushing screens enable finer control over downstream processes such as sorting, conveying, and storage. In Zenith’s lineup of heavy industrial equipment, products like the Zenith YKN Vibrating Screen and the Zenith S5X Vibrating Screen exemplify advanced technologies designed to enhance material processing efficiency. These screens are engineered to withstand heavy loads and harsh operating conditions while delivering precise particle separation, making them indispensable assets in various industries.

Advantages of Utilizing Crushing Screens

The utilization of crushing screens offers several advantages in material processing operations. Firstly, they improve product quality by ensuring consistency in particle size, which is critical for industries like aggregates production and mineral processing. Additionally, by removing oversized or undersized particles, crushing screens help optimize downstream processes, such as grinding and refining, leading to higher yields and reduced processing times. Furthermore, these screens contribute to equipment longevity by preventing damage from oversized materials, thereby reducing maintenance costs and downtime. Zenith’s range of crushing screens, combined with their crushers and mills, provides comprehensive solutions for enhancing material processing efficiency and productivity.

In conclusion, understanding the pivotal role of crushing screens in material processing is essential for maximizing efficiency and productivity in various industries. By investing in advanced screening technologies like those offered by Zenith, companies can optimize their operations and stay ahead in today’s competitive market landscape.