Don't miss our holiday offer - 30% OFF!

How Does A Jaw Crusher Mechanism Operate?

Introduction to Jaw Crushers

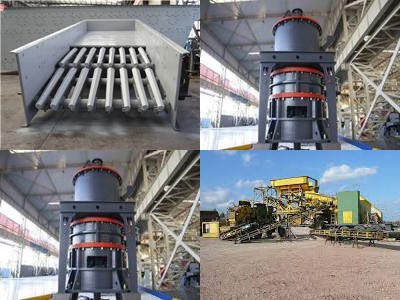

Jaw crushers are essential equipment in the mining and construction industries, used to crush large rocks into smaller pieces. These robust machines play a crucial role in various applications, from primary crushing in quarries to recycling operations. One of the key components of a jaw crusher is its mechanism, which enables the crushing of materials efficiently and effectively.

Components of a Jaw Crusher

A typical jaw crusher consists of two vertical jaws that move back and forth to crush materials. The stationary jaw remains fixed while the movable jaw exerts force on the rock by pressing it against the stationary plate. Essential components of a jaw crusher include the flywheel, toggle plates, pitman, eccentric shaft, and bearings. The flywheel stores energy during the jaw crusher’s operation, while the toggle plates control the crushing motion.

Operating Mechanism of Jaw Crushers

The operating mechanism of a jaw crusher involves the use of a toggle plate that controls the crushing process. As the eccentric shaft rotates, the toggle plate moves and allows the material to be crushed. The adjustable gap between the two jaws determines the final size of the crushed material. Properly adjusting the gap ensures the desired product size is achieved. Understanding the operating mechanism is crucial for maximizing the efficiency and productivity of a jaw crusher.

Maintenance and Safety Measures

To ensure the longevity and safe operation of a jaw crusher, regular maintenance is essential. This includes lubrication of all moving parts, inspection of wear components, and timely replacement of worn-out parts. Safety measures such as proper training for operators, wearing appropriate personal protective equipment, and following operational guidelines are paramount to prevent accidents and ensure a safe working environment.

Conclusion

In conclusion, understanding how a jaw crusher mechanism operates is fundamental for those involved in the mining and construction industries. At Zenith, we offer a range of high-quality jaw crushers designed to meet the diverse needs of our customers. Our jaw crushers are built to deliver reliable performance, durability, and efficiency, making them ideal for various crushing applications. Explore our selection of jaw crushers to find the perfect solution for your crushing needs.