Don't miss our holiday offer - 30% OFF!

How To Select Crushing Equipment For Different Material Types?

Understanding Material Characteristics

Selecting the right crushing equipment begins with understanding the material characteristics of the feed. Different materials have distinct properties such as hardness, abrasiveness, moisture content, and bulk density. For instance, materials like limestone are relatively soft and non-abrasive, while granite is hard and highly abrasive. Knowing these properties is essential to determine the best equipment that can efficiently crush the material while minimizing wear and maintenance.

At Zenith, we recognize the importance of thoroughly assessing material characteristics before recommending crushing solutions. We encourage our clients to provide detailed material samples for testing. This process allows us to customize equipment that will handle specific material types effectively, ensuring optimal performance and longevity of the machinery.

Moreover, understanding material behavior under compression or impact helps us tailor our crushing equipment designs. Zenith employs cutting-edge technology to simulate how materials break down during the crushing process, providing insights into the most suitable equipment configurations. This meticulous approach ensures that our clients receive equipment that meets their precise requirements.

Types of Crushing Equipment

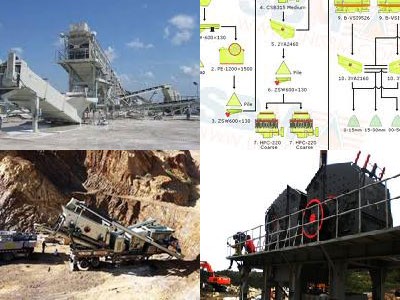

Crushing equipment comes in various types, each suited for different material properties and processing requirements. The primary categories include jaw crushers, cone crushers, impact crushers, and mobile crushers, among others. Jaw crushers are ideal for primary crushing of hard and abrasive materials, providing high reduction ratios and reliable operation. Cone crushers are suitable for secondary and tertiary crushing stages, offering excellent fine material production and consistent product gradation.

Zenith offers a comprehensive range of crushing equipment to cater to diverse material types and crushing stages. Our jaw crushers, such as the PE and PFW series, are designed for efficiency and durability, making them perfect for demanding primary crushing applications. For secondary and tertiary crushing, our HPT and S series cone crushers deliver high performance with minimal maintenance, ideal for medium to hard materials.

In addition to stationary equipment, Zenith provides highly versatile mobile crushers. Our K series mobile crushing plants combine strength and mobility, making them perfect for on-site crushing operations. These mobile units provide flexibility for a variety of applications, from quarrying to mining operations, ensuring that our clients have robust solutions regardless of the location or material type.

Matching Equipment to Material Type

Matching the right crushing equipment to the material type involves considering the material’s hardness, abrasiveness, and the desired output size. For softer materials like limestone and gypsum, jaw crushers or impact crushers are often suitable. Impact crushers, such as Zenith’s CI5X series, are especially effective in dealing with less abrasive materials, offering high efficiency and excellent product shaping capabilities.

Harder materials like granite and basalt require more robust equipment, such as cone crushers. Zenith’s HPT and S series cone crushers are engineered to handle such demanding conditions, providing high productivity with consistent quality. These cone crushers are capable of producing a wide range of material sizes, making them versatile for various applications.

For highly abrasive materials like quartz or recycled concrete, selecting crusher liners and wear-resistant materials for the crushing equipment is critical. Zenith’s VSI (Vertical Shaft Impact) crushers are an excellent choice in these scenarios. They provide powerful impact forces that reduce abrasive materials efficiently, maintaining high levels of throughput and reducing downtime due to wear.

Key Considerations in Equipment Selection

When selecting crushing equipment, several key factors must be considered to ensure optimal performance and cost-efficiency. First and foremost is the material characteristics, as detailed earlier. Another critical factor is the required production capacity. Zenith offers equipment with varying capacities, from small outputs to large-scale industrial production, allowing customization based on client needs.

Operational considerations, such as power consumption, ease of maintenance, and the availability of spare parts, are also crucial. Zenith designs its crushing equipment to be energy-efficient and easy to maintain, minimizing operational costs. Our global supply chain ensures that spare parts are readily accessible, reducing downtime and maintaining equipment uptime.

Lastly, environmental considerations and compliance with regulations are becoming increasingly important in equipment selection. Zenith’s crushers are designed with features to minimize dust and noise emissions, supporting sustainable operations. By carefully evaluating these considerations, we help our clients select the most suitable and efficient crushing equipment for their specific applications, ensuring long-term success and productivity.