Don't miss our holiday offer - 30% OFF!

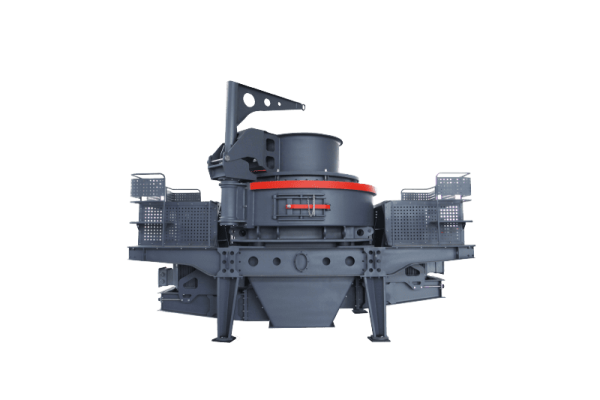

VSI6X Sand Making Machine

Lower maintenance costs, longer service life of wearing parts, bigger capacity

On account of the increasing demand for large-scale, intensification, energy saving and environment protection, and high-quality machine-made sand in the sand market, ZENITH further optimized the structure and function of the impact crusher, on the basis of thousands of impact crusher sand-shaping applications technology, and introduced a new generation of high-efficiency and low-cost sand-shaping equipment—VSI6X Sand Making Machine.

Materials:Granite, quartz, basalt, pebble, limestone, dolomite, etc.

Description

Product Advantages

To meet crushing demands of different users, VSI6X sand making machine was optimized on its structure of crushing cavity, and configured “rock on rock” and “rock on iron” crushing modes.

To ensure overall performances, VSI6X sand maker is optimized on some key parts. Besides, various national patent technologies ensure high efficiency yet low cost in crushing operation.

The service life of some key wearing parts is prolonged by 30%-200% compared with the traditional equipment in the same usage conditions.

VSI6X sand maker fully considers the safety and reliability of the equipment, and adopts a more stable and reliable dual motor drive and automatic oil lubrication.

Working Principle of Sand Making Machine

VSI6X Sand Making Machine has two feed modes – “feed at center” and “feed at center & sides”. As for “feed at center”, materials at the feed hopper firstly pass through the central hole into the high-speed spinning rotor. Next, materials hit the surrounding vortex material linerinside the vortex chamber together. Finally, finished products are discharged from the bottom discharge opening.

As for “feed at center & sides”, after materials pass through the circular hole, they are divided into two parts by the distributing tray. One part enter the high-speed rotating impeller while the other part fall from all sides of the tray.

Parameters

| Model | Sanding making | Reshaping | Sanding making | Reshaping | Speed (r/min) | Power (kW) | Overall dimension (mm) |

| Maximum feeding size (mm) | Throughput (t/h) | ||||||

| VSI6X8015 | 30 | 40 | 109-117 | 131-214 | 1300-1700 | 75×2 | 4100×2300×2750 |

| VSI6X9026 | 35 | 45 | 167-179 | 200-313 | 1200-1500 | 132×2 | 4200×2400×3150 |

| VSI6X1040 | 40 | 50 | 264-283 | 317-495 | 1100-1400 | 200×2 | 4880×2560×3725 |

| VSI6X1150 | 45 | 55 | 344-368 | 413-644 | 1000-1300 | 250×2 | 5500×2750×3950 |

| VSI6X1263 | 50 | 60 | 454-486 | 545-849 | 900-1200 | 315×2 | 5700×2980×4190 |

| VSI6X1380 | 50 | 60 | 601-643 | 721-1125 | 800-1100 | 400×2 | 7900×3260×4183 |

| VSI6X13100 | 50 | 60 | 751-804 | 940-1407 | 800-1100 | 500×2 | 7900×3260×4183 |