Don't miss our holiday offer - 30% OFF!

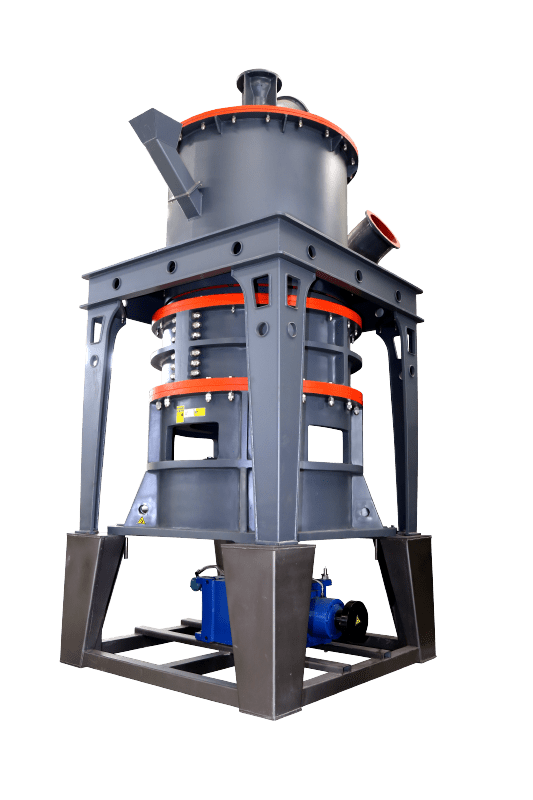

XZM Ultrafine Grinding Mill

Ultrafine powder, wide applications, excellent environmental effect

ZENITH’s XZM Ultrafine Grinding Mill is widely used for superfine powder production. The output size can reach 2500mesh (5um). It is suitable to grind soft or medium-hard materials whose moisture is below 6%. Materials should be non-explosive and non-flammable such as calcite, chalk, limestone, dolomite, kaolin, bentonite, etc. The size of the finished product can be adjusted between 325-2500 mesh.

Materials:Calcite, chalk, limestone, dolomite, kaolin, bentonite, steatite, mica, magnetite, iolite, pyrophillite, vermiculite, meerschaum, attapulgite, diatomite, barite, gypsum, alunite, graphite, fluorite, phosphate ore, potassium ore pumice, etc.

Description

Product Advantages

With the same fineness and power, the production capacity is 40% higher than that of jet grinding mill and stirred grinding mill, and the yield is twice as large as that of ball mill.

The multi-head cage-type powder selector can be configured. The fineness can be adjusted between 325-2500 meshes, and the screening rate can achieve D97≤5μm once.

The lubricating device is installed outside of the main shaft, so that lubrication without shutdown can be realized, and the production can be continued for 24h.

Silencer and noise elimination room are configured to reduce noises. Besides, the operation is organized by conforming to national environmental protection standards.

Working Principle of XZM Ultrafine Grinding Mill

After materials are sent to the grinding mill evenly and they would fall onto the dispersing plate, some on the dispersing plate are then thrown to the rim and drop to the grinding chamber. To be ground several times, materials are blown into the powder selector by airflow. Under the action of the impeller of powder selector, materials which fail to meet fineness would be sent back to grinding chamber to get another grinding while qualified powders would be collected by cyclone powder collector and discharged from the bottom as finished products. Some remaining powders would be collected by impulse dust remover and to be shook violently. This sudden shake can help kick off powders and collect them as finished products.

Parameters

| Model | XZM221 | XZM224 | XZM236 | XZM244 | XZM268 |

| Working diameter (mm) | Φ800 | Φ900 | Φ1000 | Φ1250 | Φ1680 |

| Max feed size (mm) | ≤20 | ≤20 | ≤20 | ≤20 | ≤20 |

| Final size (mesh) | 325-2500 | 325-2500 | 325-2500 | 325-2500 | 325-2500 |

| Output (kgh) | 500-4500 | 800-6500 | 1000-8500 | 2500-14000 | 5000-25000 |

| Model | XZM221 | XZM224 | XZM236 | XZM244 | XZM268 | |

| Main motor | Power | 75 | 45×2 | 132 | 185 | 315 |

| Analytical engine (FM motor) | Power | 18.5 | 18.5 | 30 | 15×4 | 18.5×5 |

| Blower motor | Power | 45 | 55 | 75 | 55×2 | 90×2 |

| Crusher | Model | PC400×600 | PC400×600 | PC400×600 | PC600×800 | PC600×800 |

| Power | 18.5 | 18.5 | 18.5 | 45 | 45 | |

| Elevator | Model | TH-200 | TH-200 | TH-300 | TH-300 | TH-300 |

| Power | 3 | 3 | 4 | 5.5 | 7.5 | |

| Vibrating feeder | Model | 300×60×1.8 Φ159-1.8 | 300×60×1.8 Φ159-1.8 | 300×60×1.8 Φ159-1.8 | 400×80×2 Φ219-2 | 400×80×2.8 |

| Power | 1.5/3 | 1.5/3 | 1.5/3 | 1.5/3 | 2.2 | |

| Discharge screw conveyor | Model | LS219-4.5/LS219-3 | LS219-5.8 | LS219-6.9/LS219-5 | LS219-5 | LS273-8.6 |

| Power | 3 | 3 | 4 | 3×2 | 5.5×2 | |

| Discharge valve | Model | ZJD-200 | ZJD-200 ZJD-250 |

ZJD-200 ZJD-250 |

ZJD-250 | ZJD-300 ZJD-200 |

| Power | 0.75 | 0.75 + 1.1 | 0.75+ 1.1 | 1.1 | 1.5+0.75 | |

| Pulse dust collectors | Model | DMC120/DMC16 | DMC16 | LDMC25 | LDMC45 | LDMC400×2 |

| Air compressor | Model | KSH150D/LG1.5-8 | KSH240D/LG2.4-8 | KSH300D/LG3.6-8 | LG6.2-8 | LG10-8 |

| Power | 11 | 15 | 22 | 37 | 55 | |