Don't miss our holiday offer - 30% OFF!

What Are The Most Effective Machines To Crush Concrete?

Concrete crushing is a crucial process in the construction and demolition industry, involving the breakdown of large concrete structures into smaller, manageable pieces. This task requires powerful and efficient machinery to ensure productivity and safety. In this article, we will explore the most effective machines for crushing concrete, highlighting their key features, benefits, and how they compare to one another. As a leading provider of heavy industrial equipment, Zenith offers a range of high-performance crushers designed to meet various concrete crushing needs.

Overview of Effective Concrete Crushing Machines

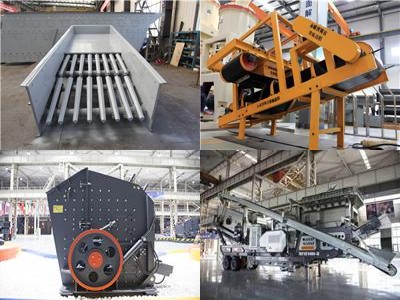

Concrete crushers come in various types, each suited for specific applications and project requirements. Jaw crushers, impact crushers, and cone crushers are among the most popular choices. Jaw crushers are known for their ability to handle large pieces of concrete, breaking them down into smaller chunks through compressive force. They are often used as primary crushers in demolition sites. Impact crushers, on the other hand, use high-speed impact force to shatter concrete, making them ideal for secondary crushing tasks and recycling projects.

Zenith offers a comprehensive line of concrete crushing machines that cater to different needs. Our jaw crushers, such as the Zenith PE series, provide robust performance and durability, handling the toughest concrete with ease. For projects requiring finer material, our impact crushers, like the Zenith CI5X series, deliver exceptional results through advanced technology and precision engineering. Each machine is designed to maximize efficiency and minimize operational costs, ensuring optimal productivity for your projects.

Key Features of Top Concrete Crushing Equipment

The effectiveness of concrete crushers is determined by several key features. One of the most critical aspects is the crushing capacity, which dictates the volume of material a machine can process within a given timeframe. High-capacity crushers are essential for large-scale demolition projects where time and efficiency are paramount. Another important feature is the mobility of the equipment. Portable and mobile crushers offer flexibility, allowing operators to move the machine to different locations on-site, thus reducing transportation costs and setup times.

Zenith’s crushers are equipped with cutting-edge features that enhance performance and usability. Our portable crushers, such as the Zenith K series, provide unparalleled mobility and ease of use. Additionally, the advanced automation and control systems integrated into our machines ensure precise operation and optimal output. Safety features, such as overload protection and easy maintenance access, are also standard in Zenith’s equipment, ensuring both operator safety and machine longevity.

Benefits of Using Advanced Concrete Crushers

Utilizing advanced concrete crushers offers numerous benefits that contribute to the success of demolition and recycling projects. Firstly, these machines significantly reduce labor costs by automating the crushing process, allowing operators to focus on other critical tasks. Advanced crushers also improve the quality of the crushed material, producing uniform and consistent aggregate sizes that are ideal for reuse in construction projects, thereby promoting sustainability and reducing waste.

Zenith’s state-of-the-art concrete crushers provide superior performance and reliability, ensuring consistent results for your projects. Our machines are designed to handle a wide range of concrete types and strengths, making them versatile tools for any demolition or recycling task. The use of advanced technology in our crushers, such as hydraulic adjustment systems and real-time monitoring, enhances efficiency and productivity, ensuring that you achieve the best possible outcomes with minimal downtime.

Comparing Popular Concrete Crushing Technologies

Different concrete crushing technologies offer unique advantages, making it essential to choose the right equipment for specific project needs. Jaw crushers are favored for their ability to handle large, tough concrete pieces and are often used in primary crushing stages. Impact crushers are preferred for their high reduction ratios and ability to produce finely crushed material, making them suitable for secondary crushing and recycling applications. Cone crushers, with their high efficiency and precise output, are ideal for producing uniform aggregate sizes in various construction projects.

Zenith provides a range of crushing technologies to suit diverse project requirements. Our jaw crushers, such as the Zenith PEW series, offer excellent durability and high throughput capabilities, making them perfect for heavy-duty demolition tasks. For projects that require high-quality aggregate production, our impact crushers, including the Zenith CI5X series, deliver exceptional performance with their advanced design and engineering. Our cone crushers, like the Zenith HPT series, provide precision and efficiency, ensuring optimal results in producing uniform and high-quality aggregates.

Choosing the right concrete crushing machine is vital for the success of any demolition or recycling project. Understanding the key features and benefits of various crushers can help you make an informed decision. Zenith, with its extensive range of high-performance crushing equipment, offers solutions that cater to different project needs, ensuring efficiency, reliability, and superior results. Contact us today to learn more about how our crushers can enhance your concrete crushing operations and drive your projects toward success.