Don't miss our holiday offer - 30% OFF!

What Determines The Price Of A 150 Tph Stone Crusher?

As demand for infrastructure projects continues to rise globally, the need for stone crushers, particularly those with a capacity of 150 TPH, remains substantial. Understanding the intricate factors that dictate the pricing of these crushers is crucial for both manufacturers and consumers. In this article, we delve into the various aspects that influence the pricing of 150 TPH stone crushers, shedding light on key components, market dynamics, and technological advancements.

Introduction to the Pricing Factors of 150 TPH Stone Crushers

When considering the price of a 150 TPH stone crusher, one must first examine the components that make up the machine. From the robust frame to the powerful motor and efficient crushing chamber, each component contributes to the overall cost. Additionally, factors such as material quality, manufacturing processes, and brand reputation play a significant role in determining the initial price tag of these crushers. For instance, premium-grade materials and advanced manufacturing techniques often result in higher upfront costs but contribute to enhanced durability and performance, ultimately impacting the price.

Key Components and Their Impact on Crusher Costs

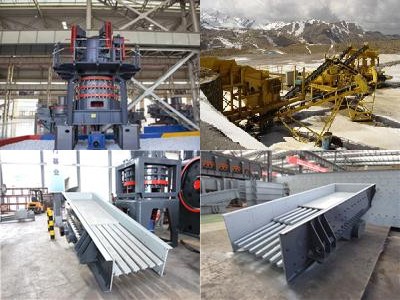

The cost of a 150 TPH stone crusher is heavily influenced by its key components, including the crushing chamber, jaw plates, bearings, and conveyor belts. High-quality materials and precise engineering of these components are essential for ensuring optimal performance and longevity of the machine. For example, durable jaw plates made from manganese steel or alloy steel may command a higher price but offer superior resistance to wear and tear, reducing maintenance costs over time. Similarly, investing in high-performance bearings and efficient conveyor systems can contribute to smoother operation and lower operational expenses, indirectly impacting the overall price.

Market Dynamics: Supply, Demand, and Crusher Pricing

The pricing of 150 TPH stone crushers is also subject to the prevailing market dynamics, including supply and demand forces. Fluctuations in raw material costs, labor expenses, and regulatory requirements can all influence the pricing strategy adopted by manufacturers. Moreover, variations in demand for stone crushers across different regions and industries can lead to price disparities based on market conditions. Understanding these dynamics and their impact on crusher pricing is crucial for manufacturers to remain competitive while ensuring profitability.

Technological Advancements and Their Role in Pricing

In recent years, technological advancements have played a pivotal role in shaping the pricing landscape of 150 TPH stone crushers. Innovations such as automation, IoT integration, and advanced material science have enabled manufacturers to enhance the efficiency, productivity, and safety of their machines. While these advancements may initially incur higher development and production costs, they often result in long-term benefits such as reduced downtime, increased throughput, and improved product quality. Consequently, the incorporation of cutting-edge technologies can influence the pricing strategy of stone crushers, positioning technologically advanced models at a premium price point.

In conclusion, the pricing of 150 TPH stone crushers is a multifaceted process influenced by various factors ranging from the quality of components to market dynamics and technological innovations. At Zenith, we pride ourselves on offering a comprehensive range of stone crushers, mills, and other heavy industrial equipment designed to meet the diverse needs of our customers. For those seeking a reliable and efficient 150 TPH stone crusher, we recommend exploring our lineup of advanced crushers equipped with state-of-the-art features and backed by our commitment to quality and service.