Don't miss our holiday offer - 30% OFF!

What Is A Silica Crusher And Why Do You Need One?

In the realm of industrial processing, particularly within the mining and construction sectors, the efficiency and effectiveness of equipment play a critical role in overall productivity. At Zenith Company, we understand these needs and offer state-of-the-art solutions for material processing. One such essential piece of equipment is the silica crusher. This article delves into the fundamentals of silica crushers, their key features and functions, and the significant benefits they bring to your operations.

Understanding the Basics of a Silica Crusher

Silica, also known as silicon dioxide, is a common mineral found in various forms such as quartz and sand. Crushing silica into finer particles is a necessary process in various industries, from glass manufacturing to construction. A silica crusher is specifically designed to handle the hard and abrasive nature of silica materials, ensuring efficient reduction of large particles into manageable sizes for further processing.

The primary function of a silica crusher is to break down bulk silica material into smaller, more uniform pieces. This process not only facilitates easier handling and transportation but also prepares the material for subsequent stages of production or refinement. At Zenith Company, we offer a range of crushers tailored to meet the specific requirements of silica processing, ensuring optimal performance and longevity.

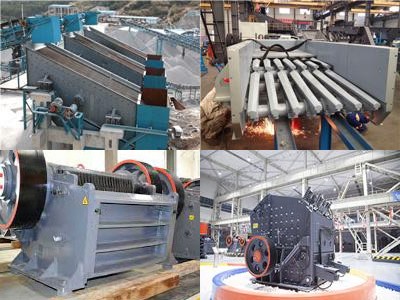

Silica crushers come in various types, including jaw crushers, cone crushers, and impact crushers. Each type has its own unique set of advantages and is selected based on the specific needs of the operation. For instance, jaw crushers are ideal for primary crushing, while cone crushers and impact crushers are better suited for secondary and tertiary crushing stages.

Key Features and Functions of Silica Crushers

Silica crushers are engineered with robust features to withstand the demanding conditions of industrial operations. One of the key features is their high crushing efficiency, achieved through advanced engineering and design. Our crushers at Zenith are equipped with powerful motors and durable components that ensure consistent and efficient crushing of silica materials.

Another significant feature is the adjustability of the crushers. This allows operators to control the size of the output material, ensuring it meets the specific requirements of their application. For example, our Zenith jaw crushers come with adjustable settings that enable precise control over the particle size, enhancing the versatility and functionality of the equipment.

Safety is also a paramount consideration in the design of silica crushers. Our products are built with safety mechanisms such as overload protection and automatic shut-off systems to prevent damage to the crusher and ensure the safety of the operators. Additionally, the ease of maintenance and accessibility of wear parts in our crushers reduce downtime, thereby increasing operational efficiency.

Benefits of Using a Silica Crusher in Your Operations

The use of a silica crusher in your operations brings numerous benefits, enhancing both productivity and cost-efficiency. Firstly, it significantly reduces the time and effort required to process large silica materials, allowing for faster throughput and higher output. This increased efficiency translates to lower operational costs and higher profitability.

Secondly, the uniformity and quality of the crushed silica material are greatly improved, which is crucial for applications requiring precise material specifications. Whether it’s for glass production, construction aggregates, or other industrial uses, our Zenith silica crushers ensure that the end product meets the highest standards of quality and consistency.

Lastly, investing in a high-quality silica crusher from Zenith means long-term reliability and performance. Our crushers are designed to withstand the rigors of continuous operation, providing a durable solution that minimizes maintenance costs and maximizes uptime. This reliability ensures that your operations can continue smoothly without unexpected interruptions, further enhancing overall productivity.

In conclusion, a silica crusher is an indispensable piece of equipment for any operation dealing with silica materials. At Zenith Company, we pride ourselves on offering top-of-the-line crushers that deliver exceptional performance and durability. Whether you’re looking to improve efficiency, ensure product quality, or reduce operational costs, our silica crushers are designed to meet your specific needs. Contact us today to learn more about our extensive range of crushers and how we can help optimize your material processing operations.