Don't miss our holiday offer - 30% OFF!

What To Look For When Buying A Crusher Screen?

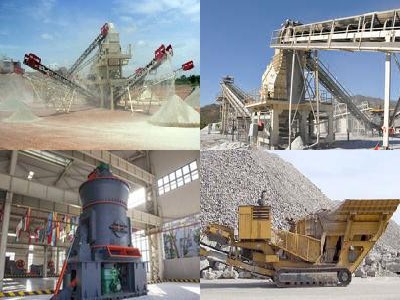

In the realm of heavy industrial equipment, crusher screens play a pivotal role in the efficiency and functionality of crushing operations. As essential components in the process of material sizing and separation, understanding the nuances of these screens becomes paramount for those venturing into the procurement process. At Zenith, a renowned provider of crushers, mills, and other industrial machinery, we recognize the significance of a well-informed purchase decision. Therefore, we present a comprehensive guide on what to look for when investing in a crusher screen, offering insights and recommendations to aid in this crucial endeavor.

Introduction: Understanding Crusher Screens

Crusher screens are integral to the crushing process, serving as the intermediary between the raw material and the final product. Essentially, they function as filters, separating the desired material from unwanted debris or oversize particles. These screens come in various types, including vibrating screens, inclined screens, and trommel screens, each designed for specific applications and material characteristics. Understanding the fundamentals of how crusher screens operate and their role within the crushing circuit is fundamental to making an informed purchasing decision.

Key Considerations in Crusher Screen Selection

When embarking on the journey of acquiring a crusher screen, several critical factors warrant consideration. Firstly, the type of material being processed dictates the type of screen required, as different materials have varying size distributions and characteristics. Additionally, the desired throughput and efficiency of the screening operation must align with the screen’s capacity and performance capabilities. Factors such as screen aperture size, inclination angle, and motion pattern profoundly impact the screening process’s effectiveness and product quality. At Zenith, our range of crusher screens encompasses a diverse selection tailored to accommodate different materials and processing requirements. From high-capacity vibrating screens to specialized trommel screens for bulk material handling, our products are engineered to deliver optimal performance and reliability.

Evaluating Crusher Screen Features and Performance

Beyond the basic specifications, evaluating the features and performance attributes of crusher screens is crucial for identifying the most suitable option. Considerations such as screen media type, wear resistance, and ease of maintenance can significantly impact long-term operational costs and uptime. Additionally, features like adjustable stroke and frequency in vibrating screens offer flexibility in optimizing screening efficiency according to specific application demands. At Zenith, our lineup of crusher screens integrates innovative design elements and robust construction to ensure durability and longevity in the most demanding operating environments. Furthermore, our comprehensive after-sales support and service network provide peace of mind, ensuring maximum uptime and operational efficiency throughout the equipment’s lifecycle.

In conclusion, the purchase of a crusher screen is a significant investment with far-reaching implications for overall operational efficiency and productivity. By understanding the nuances of crusher screen selection and evaluating key performance metrics, businesses can make informed decisions that align with their specific needs and objectives. At Zenith, we are committed to providing cutting-edge solutions and unparalleled support to empower our customers in their industrial endeavors. Explore our range of crusher screens and experience the zenith of reliability, performance, and innovation in heavy industrial equipment.