Don't miss our holiday offer - 30% OFF!

Why Choose A Gyratory Rock Crusher?

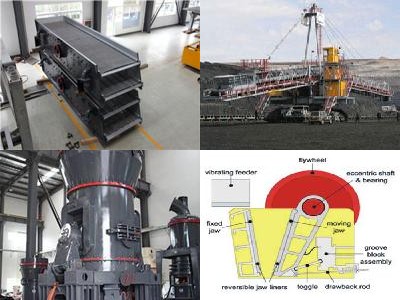

Selecting the right equipment for rock crushing is crucial for the efficiency, productivity, and overall success of any mining or quarrying operation. Gyratory rock crushers have emerged as one of the most efficient and durable choices for breaking down hard rock materials. At Zenith, we specialize in offering high-quality gyratory rock crushers that meet industry demands. In this article, we will delve deep into the benefits and features of gyratory rock crushers and explain why they are an excellent choice for your operation.

Advantages of Using a Gyratory Rock Crusher

One of the primary advantages of gyratory rock crushers is their capacity to handle large and varied chunks of material. These crushers are designed to crush even the hardest rock using a gyrating spindle, which delivers powerful crushing force and breaks down the rock into manageable sizes. This enhances the overall throughput and efficiency of mining and quarrying operations. Equipped with a large feed opening, our Zenith gyratory crushers can accommodate oversized materials, reducing the need for secondary crushing stages and enabling a smoother operation.

Another benefit is the consistent product size that gyratory rock crushers deliver. Unlike jaw crushers, which can produce uneven particle sizes due to their impact-based crushing method, gyratory crushers ensure a uniform product size that meets exact specifications. This consistency minimizes the need for additional processing and sorting, thereby reducing operational costs and improving productivity. Zenith’s gyratory crushers are engineered with precision and advanced technology, ensuring high-quality output.

Furthermore, the maintenance requirements for gyratory rock crushers are relatively low compared to other crushing equipment. Their robust design and self-tightening main shaft help prevent undue wear and tear, extending the lifespan of the crusher. Zenith offers gyratory crushers that come with easy access to service points, reducing downtime and ensuring uninterrupted operation. The ease of maintenance is a significant advantage that translates to cost savings and increased operational efficiency over time.

Efficiency and Durability of Gyratory Crushers

Gyratory crushers are known for their remarkable efficiency, capable of processing large volumes of rock with minimal energy consumption. The continuous operation mechanism ensures that the rock is crushed thoroughly and consistently, maximizing output. Zenith’s gyratory crushers are designed with energy-efficient systems, translating to reduced operational costs and lower environmental impact. This efficiency makes them an ideal choice for high-demand industries that require constant production capacity.

When it comes to durability, gyratory crushers excel due to their sturdy construction and high-quality materials. Built to withstand the harshest conditions, these machines can endure significant wear and tear without compromising performance. The rugged design is one of Zenith’s hallmarks, ensuring that our gyratory crushers offer long-term reliability even in the most rigorous applications. This durability reduces the frequency of equipment replacement and maintains operational stability.

Moreover, the streamlined design of gyratory crushers contributes to their operational efficiency. Features such as automatic lubrication systems and advanced control systems enhance the functionality of the crushers. These innovations ensure smooth and efficient operations, reducing manual intervention and operational errors. Zenith gyratory crushers are equipped with cutting-edge technology that enhances their efficiency and durability, making them a smart investment for any large-scale rock crushing project.

Key Features of Gyratory Rock Crushers

One distinguishing feature of gyratory rock crushers is their large feed opening, capable of handling heavier and larger rocks than many other crusher types. This design allows for the efficient processing of large volumes without the need for primary crushing stages. Zenith’s gyratory crushers feature an innovative feed opening that adjusts easily to accommodate different materials, optimizing the crushing process and ensuring maximum productivity.

Another key feature is the rotating spindle, which is pivotal in the gyratory crusher’s operation. The spindle’s continuous gyratory motion crushes the rock against a stationary shell, ensuring thorough and uniform crushing. Zenith offers gyratory crushers with precision-engineered spindles that deliver unmatched crushing force and dependability. Their superior design ensures long-term operational efficiency and robustness, making them a leading choice in the industry.

Additionally, advanced automation and control systems are integral to the functionality of modern gyratory crushers. These systems allow for real-time monitoring and adjustments, enhancing the overall productivity and safety of the crushing process. Zenith’s gyratory rock crushers come equipped with state-of-the-art automation technology, enabling operators to optimize performance and minimize downtime. The combination of these advanced features ensures that our crushers not only meet but exceed industry standards.

In conclusion, choosing a gyratory rock crusher from Zenith offers numerous advantages, from handling large material sizes to providing consistent product quality and reducing maintenance requirements. The efficiency and durability of our crushers, coupled with their advanced features, ensure optimum performance and long-term reliability. With Zenith’s expertise and commitment to quality, investing in our gyratory rock crushers guarantees enhanced productivity and operational success. Contact us today to learn more about our range of gyratory rock crushers and how they can benefit your mining or quarrying operation.