Don't miss our holiday offer - 30% OFF!

Why Is A Primary Crusher Machine Critical To A Mining Operation?

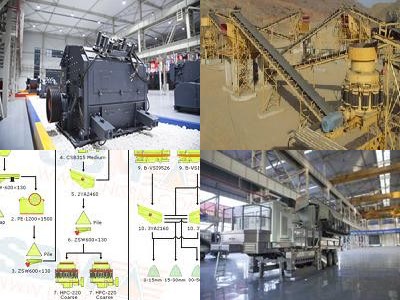

In the mining industry, the efficiency and productivity of operations hinge on various critical components, one of which is the primary crusher machine. These machines play an indispensable role in the initial stages of mineral processing by reducing large rocks into manageable sizes for further processing. At Zenith, we pride ourselves on providing state-of-the-art crushers that meet the rigorous demands of the mining sector. In this article, we will explore the essential role of primary crushers, how they enhance mining efficiency, and the key benefits they offer, all while highlighting Zenith’s superior product offerings.

The Essential Role of Primary Crushers in Mining

Primary crusher machines are pivotal in mining operations as they are tasked with the crucial first step of reducing the size of raw material. These machines are engineered to handle large, hard rocks and break them down into smaller, more manageable pieces. This initial reduction is vital because it makes subsequent processing stages much more efficient and less resource-intensive. Without primary crushers, the downstream processes would be significantly hampered, leading to increased operational costs and time delays.

At Zenith, we understand the challenges faced by mining operations, and our primary crushers are designed to meet these challenges head-on. Our crushers are built with robust materials and cutting-edge technology to ensure they can withstand the harshest conditions. This durability translates to longer operational life and reduced downtime, which is critical for maintaining steady production rates in mining operations.

Furthermore, primary crushers from Zenith are not just about breaking rocks; they are about optimizing the entire mining process. By integrating features such as automated settings and advanced monitoring systems, our crushers provide precise control over the crushing process, ensuring optimal performance and energy efficiency. This level of sophistication is essential for modern mining operations that prioritize sustainability and cost-effectiveness.

How Primary Crushers Enhance Mining Efficiency

Efficiency in mining operations is paramount, and primary crushers play a vital role in achieving it. By reducing the size of raw material early in the process, primary crushers ensure that subsequent stages, such as secondary crushing and grinding, can proceed more smoothly and quickly. This reduction in size not only speeds up processing times but also minimizes energy consumption, as smaller particles are easier to handle and process.

Zenith’s primary crushers are engineered to enhance efficiency through several innovative features. For instance, our crushers come equipped with high-capacity feeding systems that can handle large volumes of material at once, reducing the need for constant loading and unloading. Additionally, our crushers are designed with energy-efficient motors and optimized crushing chambers that maximize throughput while minimizing power consumption. This combination of high capacity and low energy use directly translates to cost savings and increased profitability for mining operations.

Moreover, the reliability of primary crushers is a key factor in maintaining efficiency. Frequent breakdowns and maintenance can severely disrupt operations, leading to significant losses. Zenith’s crushers are built to be exceptionally reliable, with features such as easy maintenance access and wear-resistant components. This reliability ensures that mining operations can run continuously with minimal interruptions, further enhancing overall efficiency.

Key Benefits of Using Primary Crusher Machines in Mining

The benefits of using primary crusher machines in mining are manifold, impacting both operational efficiency and overall profitability. One of the most significant benefits is the reduction in particle size, which facilitates easier handling and processing of materials. This not only speeds up subsequent stages but also reduces wear and tear on secondary and tertiary crushers, leading to lower maintenance costs and longer equipment lifespan.

Zenith’s primary crushers offer several specific advantages that set them apart from the competition. Our machines are designed for maximum versatility, capable of handling a wide range of materials and adapting to different mining conditions. This flexibility ensures that our crushers can meet the unique demands of any mining operation, providing consistent performance regardless of the material being processed.

Another key benefit is safety. Mining operations can be hazardous, and ensuring the safety of workers is paramount. Zenith’s primary crushers are equipped with advanced safety features, such as automated shut-off systems and protective enclosures, to minimize the risk of accidents. By prioritizing safety, we help our clients protect their workforce and maintain a safe working environment.

Lastly, the overall cost-effectiveness of primary crushers cannot be overstated. By improving efficiency, reducing energy consumption, and minimizing maintenance costs, these machines offer a significant return on investment. Zenith’s commitment to quality and innovation ensures that our primary crushers provide exceptional value, helping mining operations achieve their production goals while staying within budget.

In conclusion, primary crusher machines are critical to the success of mining operations, providing the essential first step in mineral processing. At Zenith, we are dedicated to offering top-of-the-line primary crushers that enhance efficiency, ensure reliability, and deliver significant cost savings. By choosing Zenith’s primary crushers, mining operations can achieve optimized performance, increased profitability, and a safer working environment. Explore our range of primary crushers today and discover how Zenith can help elevate your mining operations to new heights.